Steel Tray Vs Alloy Tray- Tip Top Equipment

Steel Tray Vs Alloy Tray- Tip Top Equipment

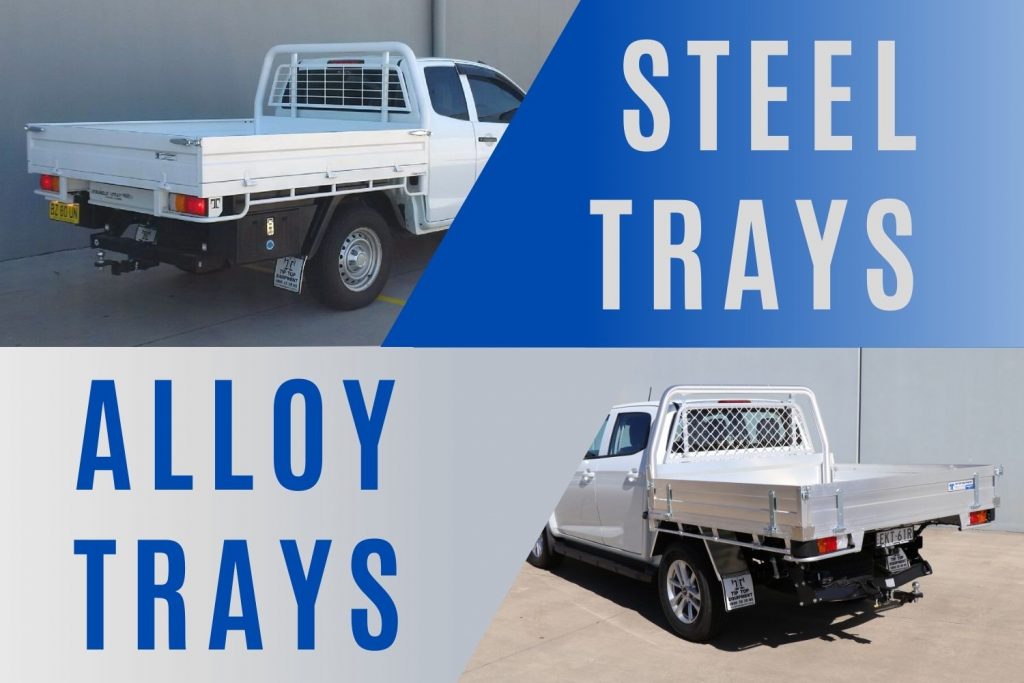

Are you in the market for a new Ute tray but don't know whether to go with steel or alloy? There are some pros and cons to each, depending on how it will be used. Let's clear up some of the misconceptions surrounding aluminium and steel trays and compare how they perform across different environments.

Benefits of an Aluminium Ute Tray

Aluminium is Lighter than Steel

Alloy trays are less than half the weight of steel trays. This means that by choosing aluminium, you can save over 140kg. For example, the Dual Cab Alloy Fleet Tray from Tip Top Equipment weighs roughly 115kg, while the steel alternative weighs in at over 250kg.

Benefits of a lighter tray:

- The vehicle will use substantially less fuel, saving you money

- There will be less wear caused to the tyres and mechanics

- The Ute will be able to carry heavier loads

Given that the average Ute has a payload of 1 tonne, or over 1000kg, having a lighter tray on the back significantly influences how much you can carry. Given that a vehicle's Gross Vehicle Mass (GVM) is an important consideration, especially for farmers or those with large load requirements, any increase to a vehicle's kerb weight caused by a steel tray will directly reduce its payload.

Resistance to Corrosion

In addition to being light and strong, aluminium is also remarkably resistant to corrosion and rust. This means that high-quality aluminium trays stay looking good for as long as you look after them, which is why we offer a Lifetime Warranty on all of our heavy-duty alloy Ute trays. Unlike steel, alloy trays do not need to be powder coated as they are naturally resistant to the elements, though this is an option if you prefer the aesthetic.

Aluminium is Safer for Carting Dangerous Materials

The magnetic properties of steel could make it hazardous in some work situations. If your occupation requires you to carry flammable gases or liquids, non-ferrous aluminium would be a safer tray option.

Tip Top Aluminium Ute Trays are Built Strong to Perform in Harsh Environments

In the past, steel trays were often considered to be superior to aluminium because of their strength. This is because steel is naturally very strong, and it is relatively easy to weld into a sturdy tray. It was also common for early iterations of aluminium trays to be poorly designed and use cheap nuts and bolts as fasteners, meaning that some people have had bad experiences in the past.

However, over the past 35 years we have worked hard at Tip Top Equipment to revolutionise the aluminium tray. With the help of technological advancements and design innovations our heavy-duty aluminium trays are built strong and rigid enough for 99% of work applications. Our Aluminium Flooring is the strongest in the market and our flooring ratings far exceed the rear suspension of all commercial Utes. This means that whilst steel trays may have greater load bearing capabilities, the suspension of the vehicle limits any benefits that may have provided.

When deciding on a Ute Tray, make sure you choose a quality tray manufacturer! Not all trays are made equal, many tray suppliers use imported flat packs, so it's important to do your research before making a purchase.

How do we make our Aluminium trays so strong?

Huck Bolts:

We are one of the only Ute tray manufacturers in Australia to use Huck Bolts, which are ultra-strong, permanent aircraft fasteners similar to huge rivets. These fasteners offer consistent clamp which eliminates bolt fatigue, and are the same product used in trains, Kenworth trucks and heavy mining applications.

Innovative Design:

Our trays have been designed by our team of experts so that each piece interlocks seamlessly with the next. No one part can be substituted, and strength is built into the design. We don't believe in one size fits all, and have spent 35 years perfecting our product.

Made-to-Order in Australia:

We make all of our Ute Trays and Accessories at our warehouse in Mount Kuring-Gai, Sydney because we value the integrity of our products. That means no flat packs, no generic parts, and only the best labour and materials go into your tray.

Our Attention to Detail:

Our team of expert designs are constantly looking for new ways to improve our designs. We are continually adding extra features to our Trays and Accessories to ensure they are as strong, durable, and easy to use as possible.

Steel Tray Considerations

Steel Trays are Beneficial for Certain Occupations

The strength and hardiness of steel make it a good choice for occupations that require the transportation of particularly hard and jagged materials.

For example, a steel tray could be a good choice if carting landscaping supplies such as dense rocks that could tumble at great force from the bucket of a front-end loader. Steel would also be useful if your work involves carting heavy-duty equipment such as steel Acrow props, jackhammer bits, or sledgehammers. A steel tray would be able to handle these tools being thrown around in the back unsecured, and would be strong enough to resist dents.

Steel Trays are Vulnerable to Corrosion

Due to the iron present in steel it is renowned for rusting. This problem is made even worse when the tray is used within 100km of the ocean, as the sea air and salt water can speed up the rusting process, leaving your tray looking stained and unattractive. While powder coating is fantastic for improving steel's resistance to corrosion, this finish is vulnerable to scratching which is easy to do when carrying sharp or heavy loads. Our ultra-strong rivets cannot be used on steel either. Instead it must be welded, making it vulnerable to cracking.

Conclusion

At Tip Top Equipment, we have had 35 years to perfect our approach to building Ute Trays. In that time we have heard horror stories from customers of rusted steel trays, as well as poor quality flat-packed alloy trays. These stories have inspired us to work hard to create products that make customers happy, and that we can be proud of.

As you may have realised, we are passionate about the power of aluminium Ute trays, but if you are still not convinced we make a mean steel tray too! Ultimately, the decision as to what you choose rests with you and your individual requirements.

Give us a call today on 1800 35 35 95 for more information or click here if you would like a quote!